Filter

-

Wall Thicknesses for Cured-in-Place Pipe Liners

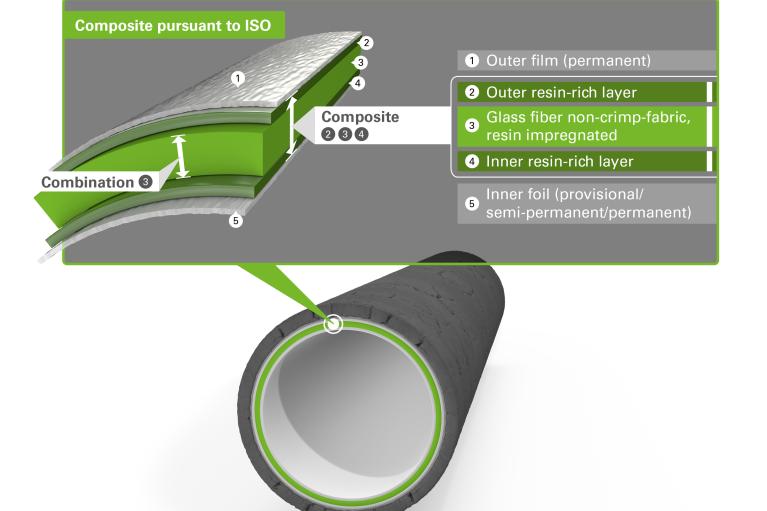

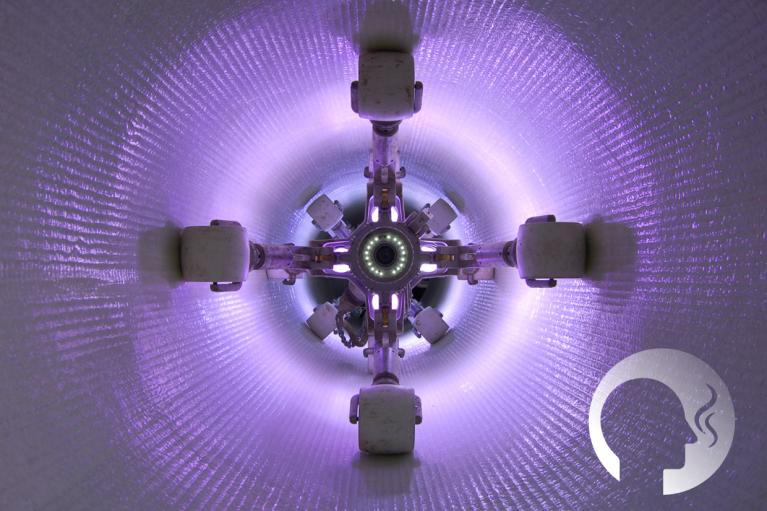

Read moreThe new version of the international product standard for cured-in-place pipe lining, ISO 11296-4, introduced a number of changes in 2018. New terms such as ‘design wall thickness’ and ‘composite’ necessitate greater adjustments for the industry than might initially be apparent. What will planners, manufacturers, testing institutes and construction companies need to consider in future? The following presents a technical article on how theory can be translated into practice, thereby ensuring greater transparency.

-

We wish you a beautiful Christmas season

Read moreChristmas is just around the corner and the year 2021 is drawing to a close. Looking back, we can say that we have also mastered this year's challenges well - also and especially thanks to our loyal customers! Thank you very much for the great cooperation and the trust you have placed in us.

With a Christmas donation campaign, we would like to do good together with you again this year.

-

Upcoming company vacations at our Saerbeck plant

Read moreTo enable us to successfully kick off the New Year together with renewed vigor, we would like to inform you of our upcoming company vacations at our Saerbeck plant.

-

Open cut trench method vs. UV-CIPP

Read more48 trillion cubic meters of potable water! That's the amount of water lost annually due to defective water pipes. To avoid such wastage, it is important for defective pipes to be rehabilitated quickly. There are different remediation options for this.

-

Styrene-free SAERTEX-LINER ENVIRONMENT now with DIBt approval

Read moreThe styrene-free SAERTEX-LINER ENVIRONMENT was the first GRP liner with styrene-free VE resin on the market to be approved by DIBt. This improves the range of products offered by SAERTEX multiCom for the trenchless rehabilitation of wastewater pipes, especially for applications where it is important to avoid the typical odor of styrene.

-

Improved Transportation and Storage Conditions for the SAERTEX-LINERS MULTI and GAS

Read moreOver recent months our team has been working intensively on improving the transport and storage conditions for our pre-impregnated GRP LINERS. We are pleased to inform you now that temperature control (cooling) for a large number of our GRP LINER shipments is no longer necessary. Moreover, there are also positive new developments regarding the storage conditions for some product ranges.