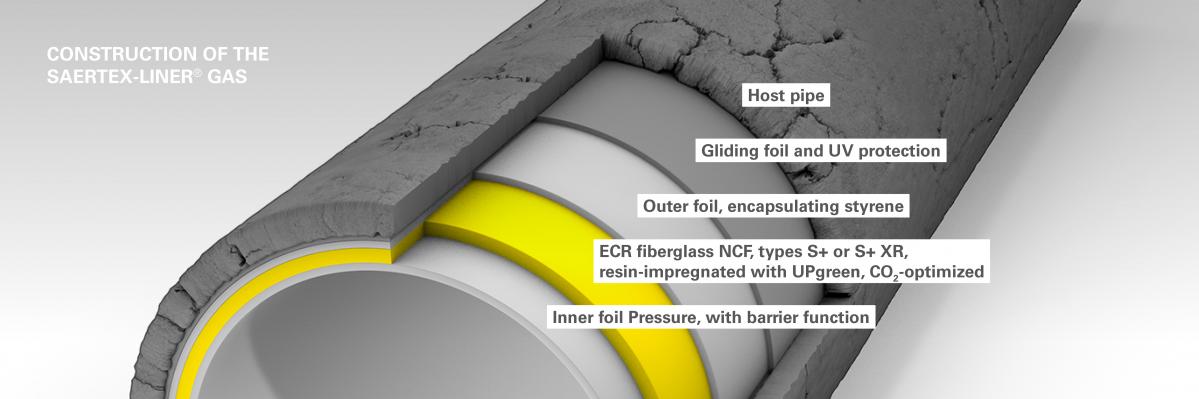

Pressure-resistant, fully structural and CO2-optimized: The WRc-certified SAERTEX-LINER GAS is the first choice for the trenchless rehabilitation of gas supply lines using the UV-CIPP process. It comes in two designs, each optimally matched to the specific application:

- Type S+: low-cost alternative for low operating pressures up to 2 bar

- Type S+XR: to resist higher pressures

Benefits

WRc-certified for gas applications

Our SAERTEX-LINER GAS is certified by the independent Water Research Center (WRc) for the rehabilitation of steel and cast-iron gas supply lines. In addition to mechanical tests, the GRP pipe liner also fulfills the requirements for permeability and chemical resistance against a wide range of gases.

High flow rate

Smooth surfaces coupled with low wall thicknesses relative to diameter maximize flow rate in supply pipes.

Customized solution package

You, too, can benefit from our wide range of additional services. Our experienced experts and engineers provide support to ensure the smooth progress of your construction project,from the conception phase through to the successful completion of your project.

SAERTEX-LINER UPgreen: CO2-optimized

The climate-friendly manufacturing process for our UP resin systems saves an average of 250,000 kg CO2 per quarter. On request, we can provide you with a certificate showing the CO2 savings achieved by your projects.

Variants

| Product range | SAERTEX-LINER® GAS |

|

|---|---|---|

| Utilization | Gas | |

| Resin type | UP | |

| Temperature and media resistance | WRc | |

| Styrene free? | no | |

| Design | Typ S+ | Typ S+ XR |

| Host pipe profile | Circular | Circular |

| Pressure Application | • | • |

| Operating Pressure [bar] | up to 2 | up to 33 |

| Fully statically loadable | • | • |

| DN [mm] | 250–1,200 | 250–1,200 |

| Composite wall thickness [mm] | 4–12 | 4.3–12.3 |

| Foils | ||

| Outer foils: | ||

| - Integrated gliding and UV light protection foil | • | • |

| - Permanent foil with barrier function Inner | • | • |

| Inner foil with barrier function: | ||

| - Pressure (permanent) | • | • |

| Mechanical Characteristics | ||

| Short-term circumferential E modulus [N/mm²] | ≥ 20,500 | |

| Long-term circumferential E modulus [N/mm²] | 16,000 | |

| Short-term bending E modulus [N/mm²] | ≥ 16,800 | |

| Short-term bending stress [N/mm²] | ≥ 270 | |

| Long-term bending stress [N/mm²] | 210 | |

| Reduction factor according to DIN EN 761: | ||

| - 50 years [after 10,000 hours] | 1.28 | |

Downloads

How To

INSTALLATION SAERTEX-LINER H2O/DRUCK/GAS

References

References

A look at our latest work - Find out more.

August 2017

Would you like to see which projects we have recently completed? We would be happy to introduce you to our top references!