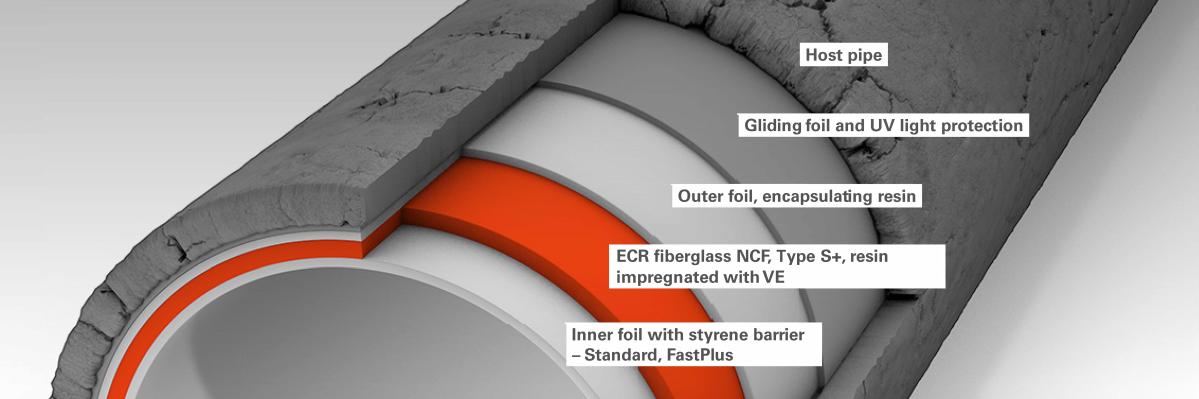

Our SAERTEX-LINER INDUSTRY is a combination of vinyl ester (VE) and ECR fiberglass that gives it high media and temperature resistance. It is ideal for use in the trenchless rehabilitation of industrial wastewater pipes and we adapt our product to your application – based on the proven Type S+.

Benefits

Resistant to high temps and corrosives

By combining the corrosion resistance of ECR fiberglass with the chemical resistance of vinyl ester (VE), SAERTEX-LINER® INDUSTRY is engineered to withstand the harsh effects of industrial wastewater. Since the liner’s high-resistance properties are dependent on the temperature and concentration of the chemicals, our product engineers will consult with you to determine if it is suitable for your application.

Installation-friendly and time-saving

Low wall thicknesses shorten curing times, and the reduced weight of the liner optimizes handling. The liner’s construction allows higher pulling forces and prevents it from overstretching. The optional “FastPlus” inner foil remains in the liner after curing, saving time.

Technical service life of 100 years

Our unique ECR fiberglass reinforcement is based on multiaxial fabric technology that withstands high mechanical stresses. SAERTEX-LINER® INDUSTRY offers the same excellent reduction factor in the 20,000-hour test as our SAERTEX-LINER® MULTI, S+ product, which means a technical service life of 100 years.

Gliding and UV light protection foil

SAERTEX-LINER® INDUSTRY offers an integrated gliding and UV light protection foil as standard; there is no extra charge. This eliminates an additional gliding foil for liners up to DN 600 and a max. weight of 2.5 tons.

Variants

| Product range | SAERTEX-LINER® INDUSTRY |

|---|---|

| Resin type | VE |

| Temperature and media resistance | +++ |

| Styrene free? | no |

| Design | Typ S+ |

| Host pipe profile | Various |

| Application | Gravity |

| Fully statically loadable | • |

| DN [mm] | 150–1,000 |

| Composite wall thickness [mm] | 3–10 |

| Foils | |

| Outer foils: | |

| - Integrated gliding and UV light protection foil | • |

| - Permanent foil with barrier function Inner | • |

| Inner foil with barrier function: | |

| - Standard (temporary) | • |

| - FastPlus (semi-permanent)* | Selectable |

| Mechanical Characteristics | |

| Short-term circumferential E modulus [N/mm²] | ≥ 20,500 |

| Long-term circumferential E modulus [N/mm²] | 16,000 |

| Short-term bending E modulus [N/mm²] | ≥ 16,800 |

| Short-term bending stress [N/mm²] | ≥ 270 |

| Long-term bending stress [N/mm²] | 210 |

| Reduction factor according to DIN EN 761: | |

| - 50 years [after 10,000 hours] | 1.28 |

| - 100 years [after 20,000 hours] | 1.31 |

*FastPlus verfügbar für DN 200 bis DN 1000 max. WD 10 mm

Extra time savings: option FastPlus

This rugged inner foil remains inside the liner after curing and saves your team about 1 hour of installation time for every 100 meters of liner. FastPlus also makes it easier to introduce the UV source, even under difficult installation conditions.

Chemical resistance tests

Once you provide information on the type of chemicals, their concentration, and the maximum temperatures of the flow media, our liners are then specifically tested to ensure their suitability for your application. Our product specialists will be glad to advise you.

Downloads

How To

HOW TO INSTALL A GRP LINER FOR UV CIPP - SAERTEX-LINER INSTALLATION (EN)

References

References

A look at our latest work - Find out more.

May 2019

Would you like to see which projects we have recently completed? We would be happy to introduce you to our top references!