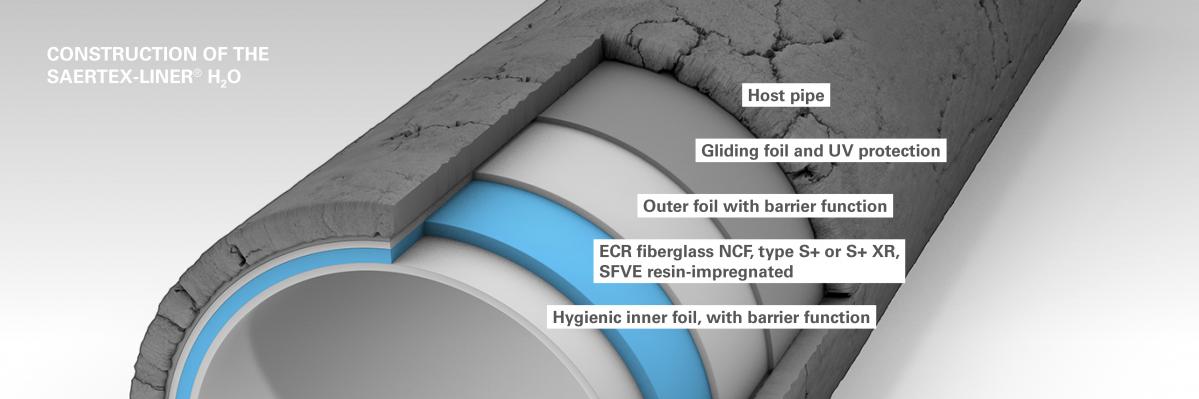

Pressure-resistant, hygienic, award-winning: SAERTEX-LINER® H₂O offers superior mechanical characteristics for the trenchless rehabilitation of potable water supply lines using the UV-CIPP process. Our UV-cured GRP pipe liner is approved in over 14 countries and won the ISTT Innovation Award in 2019. It is available in two design options:

- Type S+: low-cost alternative for low operating pressures up to 1 bar

- Type S+ XR: suitable for potable water supply lines at pressures up to 33 bar

Benefits

Proven innovative technology

SAERTEX-LINER® H₂O has been used on 300 UV-CIPP installations on over 100 projects to date and has proven itself worldwide – from Berlin to Valencia, Shanghai to Stockholm, and Moscow to New Jersey.

Advanced hydraulic engineering

Smooth surfaces coupled with low wall thicknesses maximize flow rate in supply pipes.

Fully structural

The tight-fitting, independent pipe liner absorbs inner and outer loads and withstands pressures up to 33 bar. It is also certified to Class A (DIN EN ISO 11295) and to Class IV (AWWA M28).

With support services

Our wide range of services, including ongoing support from our product experts and engineers, helps ensure the smooth progress of your construction project from the conception phase through to its successful completion.

Variants

| Product range | SAERTEX-LINER® H2O |

|

|---|---|---|

| Utilization | Potable water | |

| Resin type | SFVE | |

| Certification** | NSF, AS/NZS4020 and more |

|

| Styrene free? | yes | |

| Design | Typ S+ | Typ S+ XR |

| Host pipe profile | Circular | Circular |

| Pressure Application | • | • |

| Operating Pressure [bar] | up to 1 | up to 33 |

| Fully statically loadable* | • | • |

| DN [mm] | 250–1200 | 250–1200 |

| Composite wall thickness [mm] | 4–12 | 4,3–12,3 |

| Foils | ||

| Outer foils: | ||

| - Integrated gliding and UV light protection foil | • | • |

| - Permanent foil with barrier function Inner | • | • |

| Inner foil with barrier function: | ||

| - Hygienic (Permanent) | • | • |

| Mechanical Characteristics | ||

| Short-term circumferential E modulus [N/mm²] | ≥ 12.950 | ≥ 20.500 |

| Long-term circumferential E modulus [N/mm²] | 9.450 | 16.000 |

| Short-term bending E modulus [N/mm²] | ≥ 15.000 | ≥ 16.800 |

| Short-term bending stress [N/mm²] | ≥ 230 | ≥ 270 |

| Long-term bending stress [N/mm²] | 165 | 210 |

| Reduction factor according to DIN EN 761: | ||

| - 10 years [after 2,000 hours] | 1.37 | |

| - 50 years [after 10,000 hours] | 1.28 | |

*Structural classification for pressure applications | Class A DIN EN ISO 11295 // Class IV AWWA M28

**Australia, New Zealand, Brazil, China, Israel, Italy, Poland, Russia, Slovakia, Spain, Czech Republic, Belarus

Project support from beginning to end

- Engineering services, e.g. feasibility studies, structural calculations according to DWA and ASTM, approvals, etc.

- Practical training programs for your team

- Technical support from our application engineers

- UV-CIPP installation equipment to rent or buy

A six-month shelf life means greater flexibility

SAERTEX-LINER® H₂O impregnated at our plant and properly stored at your facility has a maximum stable shelf life of six months, allowing you some flexibility on your project.

Downloads

How To

INSTALLATION SAERTEX-LINER H2O/DRUCK/GAS

References

References

A look at our latest work - Find out more.

August 2020

December 2020

August 2020

January 2018

Would you like to see which projects we have recently completed? We would be happy to introduce you to our top references!