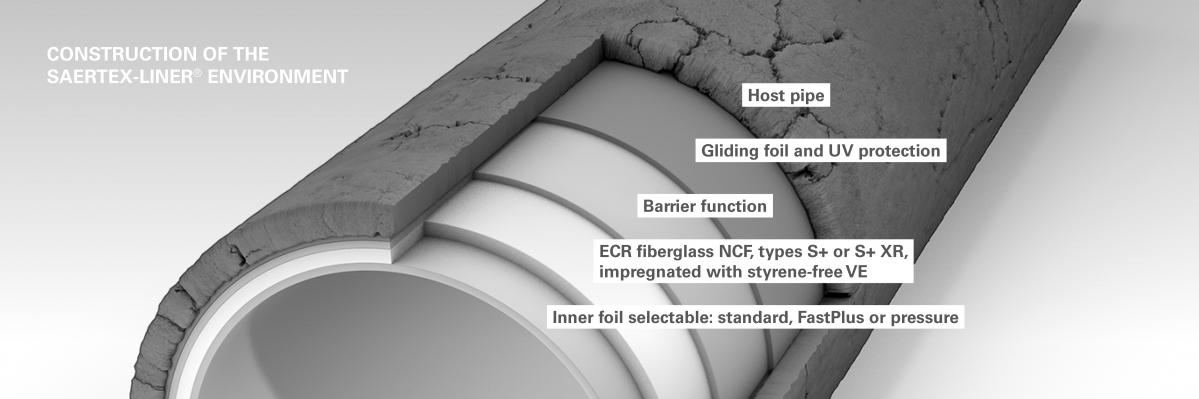

SAERTEX-LINER® ENVIRONMENT is the styrene-free option in our GRP pipe liner product range. With no styrene emissions, this liner is ideal for the trenchless rehabilitation of wastewater and stormwater pipes in high traffic public spaces and residential areas. It is available in two design options:

- Type S+: strong mechanical properties for numerous applications

- Type S+ XR: suitable for pressure lines up to 33 bar

Benefits

No styrene odor

SAERTEX-LINER® ENVIRONMENT is impregnated with styrene-free vinyl ester resin, making it ideal for UV-CIPP rehabilitation work performed in high-traffic areas and other public spaces.

Impressive mechanical properties

This styrene-free liner offers impressive mechanical properties that make it suitable for many applications, such as a long-term circumferential E modulus of 9,450 N/mm² and an excellent preliminary reduction factor of 1.37 after 2000 hours of testing.

DiBT approved

SAERTEX-LINER® ENVIRONMENT is the first fiberglass-reinforced pipe liner impregnated with styrene-free VE resin on the market approved by the German Institute for Building Technology (DiBT).

Installation-friendly construction

The construction of SAERTEX-LINER® ENVIRONMENT allows higher pulling forces and prevents the liner from overstretching. Its low weight makes for easier handling, and the lower wall thicknesses shorten curing times. The “FastPlus” option saves even more installation time because the inner foil stays in place after curing.

Variants

| Product range | SAERTEX-LINER® ENVIRONMENT |

||

|---|---|---|---|

| Utilization | municipal wastewater and rainwater | ||

| Resin type | SFVE | ||

| Temperature and media resistance | + | ||

| Styrene free? | yes | ||

| Design | Typ S+ | Typ S+ XR | |

| Host pipe profile | Various | Circular | Circular |

| Application | Gravity | Pressure | Pressure |

| Pressure Application | • | ||

| Operating Pressure [bar] | up to 1 | up to 33 | |

| Fully statically loadable* | • | • | • |

| DN [mm] | 150–1,500 | 250–1,200 | 250–1,200 |

| Composite wall thickness [mm] | 3–12 | 4–12 | 4.3–12.3 |

| Foils | |||

| Outer foils: | |||

| - Integrated gliding and UV light protection foil | • | • | • |

| - Permanent foil with barrier function Inner | • | • | • |

| Inner foil with barrier function: | |||

| - Standard (temporary) | • | ||

| - FastPlus (semi-permanent)** | Selectable | ||

| - Pressure (permanent) | • | • | |

| Mechanical Characteristics | |||

| Short-term circumferential E modulus [N/mm²] | ≥ 12,950 | ≥ 20,500 | |

| Long-term circumferential E modulus [N/mm²] | 9,450 | 16,000 | |

| Short-term bending E modulus [N/mm²] | ≥ 15,000 | ≥ 16,800 | |

| Short-term bending stress [N/mm²] | ≥ 230 | ≥ 270 | |

| Long-term bending stress [N/mm²] | 165 | 210 | |

| Reduction factor according to DIN EN 761: | |||

| - 50 years [after 10,000 hours] | 1.37 | 1.28 | |

*Structural classification for pressure applications | Class A DIN EN ISO 11295 // Class IV AWWA M28

**FastPlus available for DN 200 to DN 1500 max WD 12 mm

Proven results

SAERTEX-LINER® ENVIRONMENT still retained excellent mechanical characteristics after 2000 hours of testing, meeting the requirements of a wide range of typical rehabilitation projects (as of 4/2021). Contact us for the current status of the 10,000 hour test.

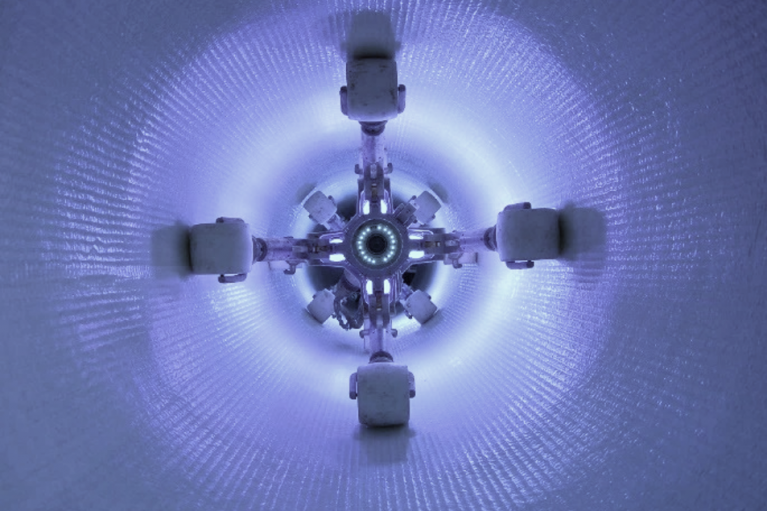

Extra time savings: option FastPlus

This rugged inner foil remains inside the liner after curing and saves your team about 1 hour of installation time for every 100 meters of liner. FastPlus also makes it easier to introduce the UV source, even under difficult installation conditions.

How To

HOW TO INSTALL A GRP LINER FOR UV CIPP - SAERTEX-LINER INSTALLATION (EN)